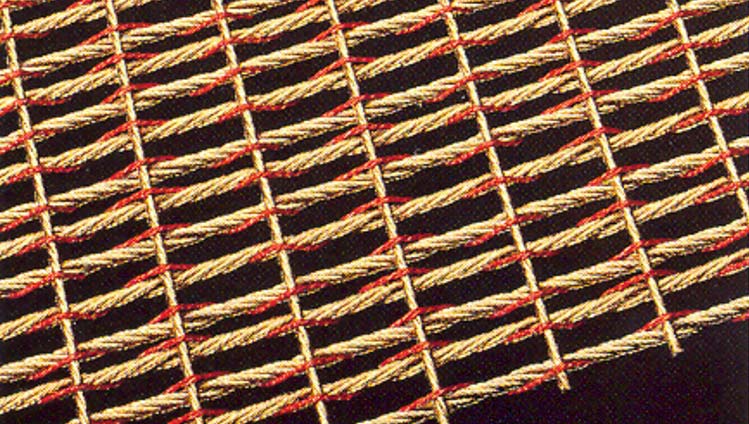

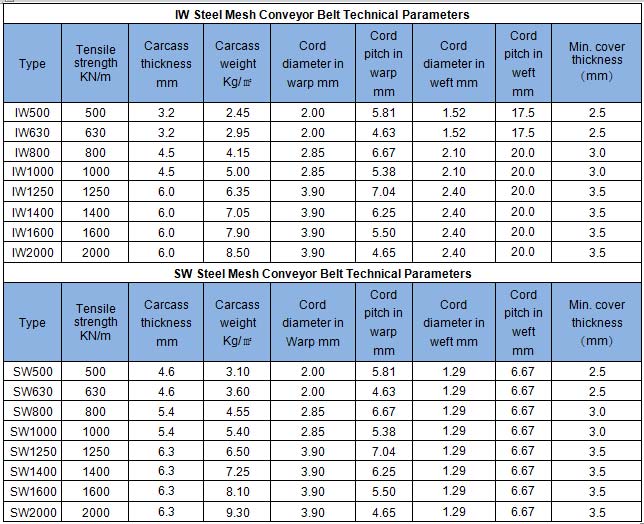

Utilizing IW/SW steel mesh as the carcass for conveyor belting imbues the belt with excellent anti-tear properties, effectively guarding against piercing while maintaining good heat resistance. IW conveyor belts are well-suited for applications such as ore handling, quarries, coal and ore terminals, where impact resistance and anti-tear properties are paramount. They are also ideal for use in metallurgical sintering and coke plants due to their high-temperature resistant properties, as well as for bucket wheel machines requiring high flexibility.

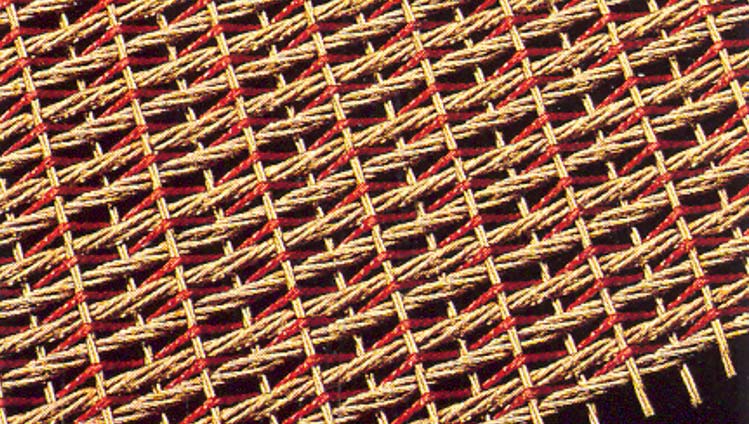

On the other hand, SW conveyor belts are specifically designed for vertical conveying of materials and find wide application in industries such as metallurgy, chemical, cement, electricity, and grain handling.